Bridge Inspection Unit – Aspen A-52

Versatile Bridge Inspection and Maintenance Truck with Interchangeable Platform

Bridge Inspection and Maintenance Unit – Versatility and Reach

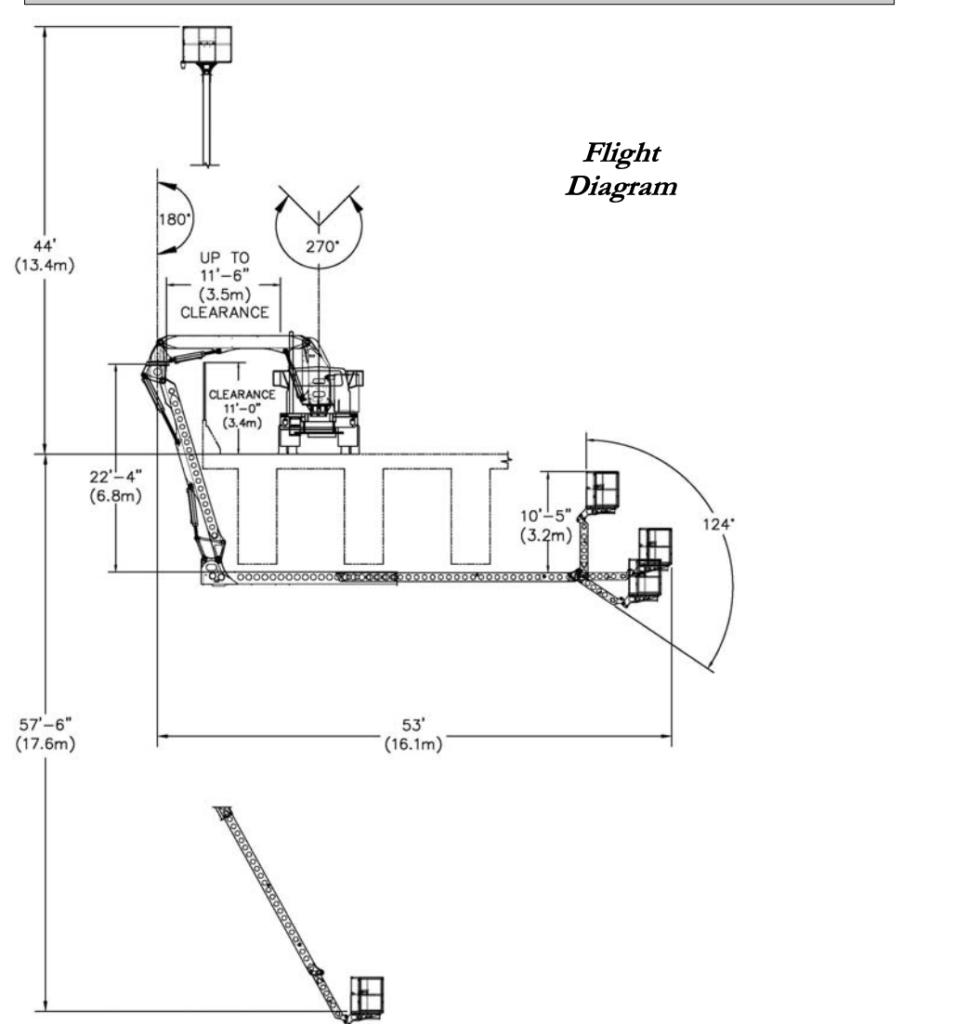

Bridge inspection and maintenance can require very flexible equipment to manage the tasks associated with doing a thorough job. The Aspen A-52 was designed as a dual functioning machine – one that can be used for bridge inspection and also for maintenance tasks, while equipped with the latest technological advances. Using the ASPEN A-52’s articulating boom, inspectors have the flexibility to inspect all areas of the bridge; above, below and alongside, with an impressive 53 feet of horizontal penetration. An interchangeable, 1,500 lb capacity maintenance walkway can be installed for the heavy duty tasks that require additional room and extra tools to complete the work.

Bridge Inspection and Bridge Maintenance – Interchangeable Platforms

Bridge inspection and bridge maintenance require different personnel and different tools and equipment. For maximum flexibility, the Aspen A-52 can be fitted with either of two fully-interchangeable platforms.

- A three person, 40″ x 60″ x 44″ aluminum platform comes standard. This 700 lb. capacity inspection platform comes equipped with an easy entry gate and is attached to the end of the articulating fourth boom, providing a full range of movement and articulation. A fiberglass platform is also available.

- A large, three stage, 3.5′ x 49′ interchangeable maintenance walkway, which attaches to the end of the second boom. It has a 1,500 lb. capacity and provides a large working space for all types of repair work.

Stabilizing Systems for Bridge Inspection

The Aspen A-52 is fitted with stabilizing systems which allow operators the advantage of being able to move the truck while the platform is deployed.

As is the case with all Aspen Aerials equipment, OUTRIGGERS ARE NOT REQUIRED.

- A full-length subframe provides strength and stability.

- Axle locks unitize the chassis and truck axles.

- A counterweight at the base of the pedestal rotates with the unit, always staying within the width of the chassis.

- A hydraulically sliding counterweight is installed under the truck so that the weight can be positioned in the most optimum counterbalanced position.

- An interlock system tied to the controls maintains operation within the unit’s full range of stability.

- A full color monitor is provided, at the pedestal, enabling operators to constantly monitor boom and turret movements.

Advanced Control System

As the most advanced microprocessor control system available, the Graphical Terminal Interface includes a color display depicting unit operation and individual function performance while monitoring the unit’s parameters, hydraulics and enabling simple troubleshooting.

- Controls, with wireless capabilities, are included at both operator stations. A communication system is also provided with speakers in the cab, at the turntable, and with hands-free operation at the platform. The platform station operates in the “hands-free” mode.

Adjustable Turntable

Two rotating turntables, as well as multiple articulating and telescoping booms, allow the platform to deploy off of either side of the truck to access any structure. Turntable #2 comes equipped with a hydraulic leveling system, providing smooth platform movement. In addition, the operator can make manual adjustments of +/- 5 degrees to compensate for any super-elevation of the bridge. Without the need for leveling arms, the ASPEN A-52 offers technicians the exceptional ability to clear fences that are up to 11 feet tall.