Bridge Inspection Unit – Aspen Aerials B-32 – Lightweight Bridge Access Unit

Bridge Inspection and Maintenance Unit – Aspen B-32

Bridge inspection and maintenance sometimes requires lightweight equipment. The Aspen B-32 was built and is often used to gain access to Bridges with weight restrictions. Available for purchase at under 26,000 total GVW *, the ASPEN B-32 is designed to operate on bridges where heavier trucks and equipment cannot be used. This is accomplished without sacrificing the features needed to access critical areas of the bridge. In this configuration, a Commercial Driver’s License (CDL) is not required. Standard Features include two turntables, three booms and a hydraulic platform extension. The B-32’s unique design allows personnel to operate above ground level as well, even when not operating on a bridge. This feature succeeds in providing additional versatility to bridge inspection fleets.

Higher Slope and Grade Access

Bridge inspection equipment should always comply with ANSI standards. All Aspen Aerials units are tested and compliant in accordance with ANSI A92.8 standards. The B-32 is also available in other configurations that allow operation on slopes and grades that exceed ANSI’s minimum requirements.*

Cab Controls for Bridge Inspection

Bridge inspection and maintenance set-up operation and system monitoring can be done from inside the cab of the Aspen Aerials unit. A graphical terminal interface is in full view of the truck operator. The graphical terminal interface includes a color display that depicts unit operation and the performance of individual functions, all while monitoring the unit’s parameters and hydraulics, and enabling simple troubleshooting.

Wireless controls are used remotely and at the platform. A communications system is also provided with speakers in the cab, at the turntable, and at the platform. The platform station operates in a “hands-free” mode.

Adjustable Turntable

Two rotating turntables and multiple articulating booms allow the platform to deploy off either side of the truck to access bridge structures. Turntable #2 comes equipped with a hydraulic leveling system, which provides smooth platform movement. In addition, the operator can make manual adjustments of +/- 9 degrees to compensate for any super-elevation of the bridge.

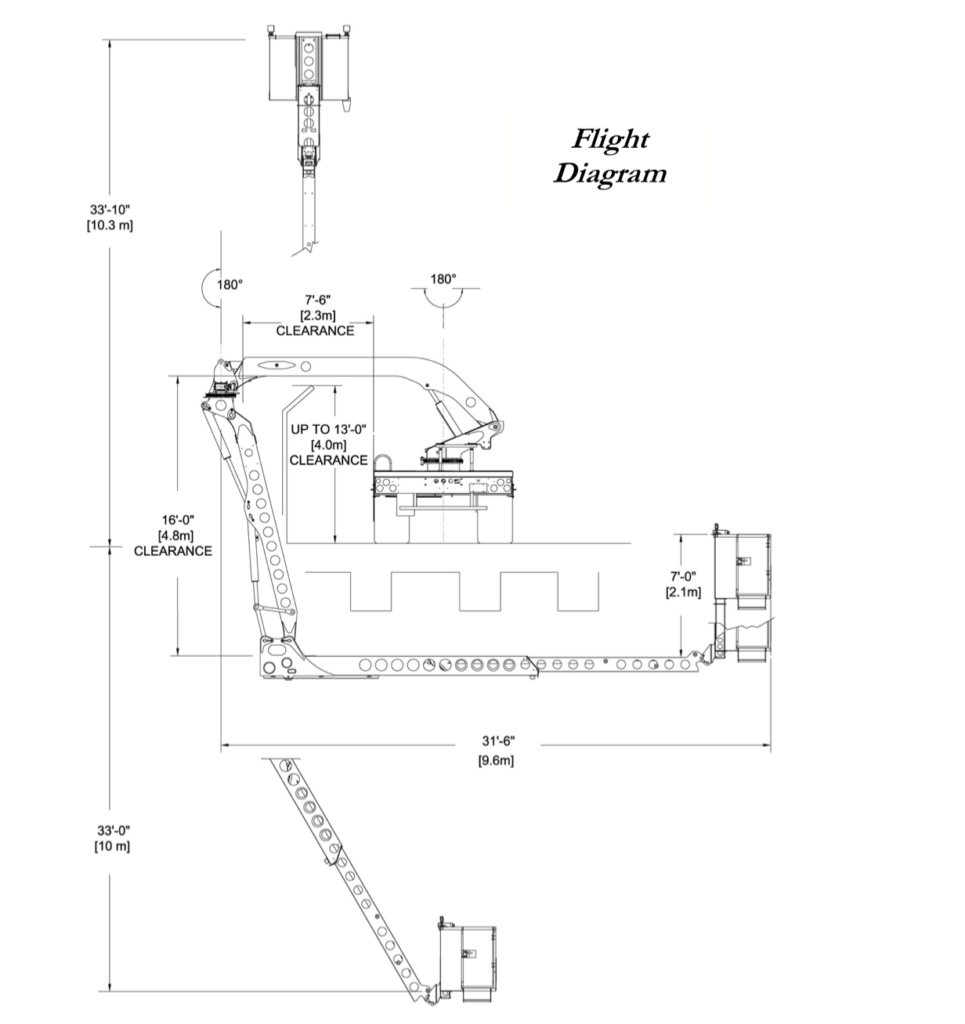

Overhead Reach

Unlike many bridge inspection trucks, the Aspen Aerials B-32 has been designed to work overhead, even when not operating on a bridge. With Boom #1 in its upward position, the other booms can clear the group and full overhead reach can be obtained. This additional flexibility makes the B-32 a versatile tool in your fleet.

Platform Extension

Bridge inspection requires a platform with substantial capacity. The ASPEN B-32 has a two-man, 600 lb. capacity platform that is equipped with a hydraulic vertical extension. This feature allows technicians to easily move up into tight areas for a close-up inspection.

Stabilizing Systems

Bridge inspections require that large equipment be stationed on the deck of the bridge itself, which leads to impeded pedestrian and vehicular traffic. As is the case with all Aspen Aerials equipment, the B-32 is fitted with stabilizing systems which allow operators the advantage of being able to move the truck while the platform is deployed. This means that bridge inspections conducted with Aspen Aerials equipment are completed in less time and with less interruptions.

With Aspen Aerials, OUTRIGGERS ARE NOT REQUIRED.

- An integral subframe providing strength and stability.

- A front torsion bar maximizes the front axle weight distribution.

- Rear axle locks unitize the chassis and truck axles.

- Counterweights that never extend past the edge of the truck during operation.

- A hydraulically sliding counterweight is available installed under the truck so that the weight can be positioned in the most optimum counterbalanced position.

- An interlock system tied to the controls maintains operation within the unit’s full range of stability.

*final weights will vary and under 26,000 GVW may not be available, depending on factors such as chassis selection and slope/grade requirement.